Switchgear Servicing and Retrofit

In general, the switchgear can be in one of the following life cycle stages regarding the years of life: – Early life: up to 9 years – Mid life: from 10 to 20 years – Late life: more than 20 years Duration stages will be decreased if the number of apparatus operations exceeds the following typical values.

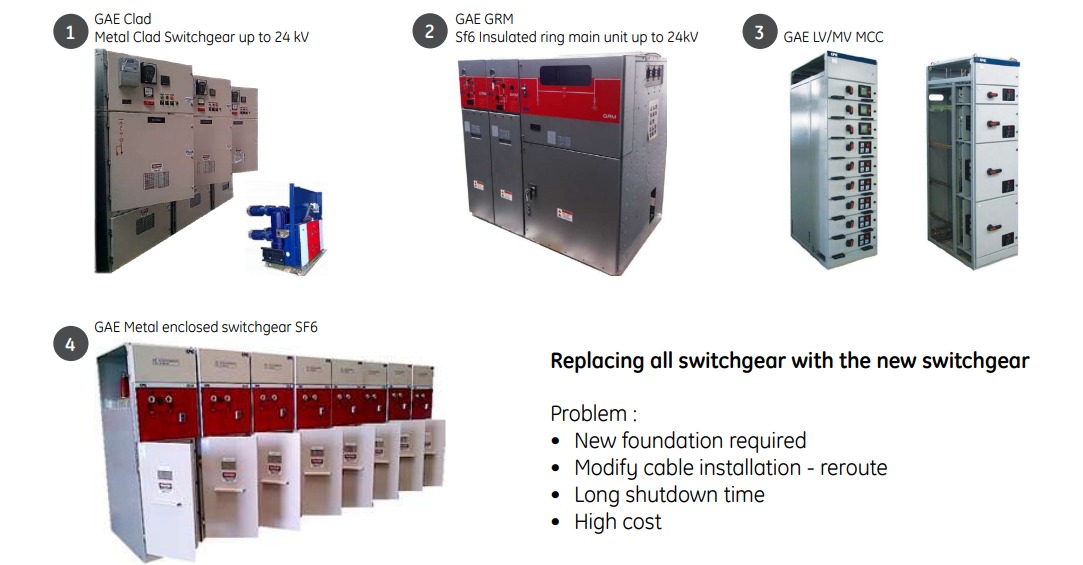

Install complete new switchgear

Periodic preventive maintenance is recommended for all electrical equipment to protect it from adverse effects of heat, dust, moisture, and other contaminants and to identify incipient problems before failure occurs.

Refurbishment Services include the following preventive maintenance activities:

• Complete visual and mechanical inspection

• Clean and lubricate all mechanisms

• Perform mechanical function tests

• Perform electrical function tests

Refurbishment Services include the following preventive maintenance activities:

• Complete visual and mechanical inspection

• Clean and lubricate all mechanisms

• Perform mechanical function tests

• Perform electrical function tests

As equipment ages, components begin to wear and insulation deteriorates leading to electrical leakage, tracking, and possible flashover. Damage is normally evident on the surface of insulating members and if it has not progressed to significant depths, can usually be resurfaced. Reconditioning Services enables you to renew your aging equipment without the cost of rebuilding or replacement—extending the useful life and improving reliability. These services include the same preventive maintenance activities included in the refurbish services plus the following :

• Perform as refurbish step

• Complete disassembly

• Inspection of all parts for physical integrity

• Worn parts are replaced

• Current-carrying elements are reconditioned

• Reassembly per manufacturer's specifications

• Perform as refurbish step

• Complete disassembly

• Inspection of all parts for physical integrity

• Worn parts are replaced

• Current-carrying elements are reconditioned

• Reassembly per manufacturer's specifications

Circuit breaker retrofit is a cost-effective switchgear modernization solution to address upgrades needs in low budget times. Retrofit breakers can replace circuit breakers phased out by current production versions, mechanically and electrically engineered to adapt to the existing switchgear. The result is a noticeable improvement on reliability, safety and performances, as the switching devices are the switchgear part mostly subject to electrical and mechanical aging.

Reason to retrofit:

• Breakers are beyond expected lifetime

• Existing breaker technology is old (Oil/SF6 CB)

• Spare part are difficult to locate, and costly

• Operational staff is trained and confident with the operation of the existing substation

• Safety aspects : fire and explosion hazard bulk oil

Reason to retrofit:

• Breakers are beyond expected lifetime

• Existing breaker technology is old (Oil/SF6 CB)

• Spare part are difficult to locate, and costly

• Operational staff is trained and confident with the operation of the existing substation

• Safety aspects : fire and explosion hazard bulk oil