GE M60 | Motor Protection System

Comprehensive protection for medium and large motors. The M60, a member of the UR Family, is a full featured relay designed for the protection and management of medium and large horsepower motors. The M60 incorporates advanced features such as an enhanced thermal model, standard and custom thermal limit curves, current unbalance biasing, running and stopped exponential cooling curves, optional RTD modules, and hot/cold motor compensation. Use the M60 in protection applications requiring complex I/O configurations and high-speed communications.

Applications

- Protection and control of most popular construction type medium to large thee-phase induction motors

- Automation or process control functionality

- Protection of medium to large synchronous motors when paired with the SPM Synchronous Motor Protection System

- Stand-alone protection or component in automated substation control system

Key Benefits

- Advanced motor protection and control elements including a flexible and powerful thermal model and standard, custom and voltage dependant overload curves

- Integrated automation and process control functions

- Simplified programming with the EnerVista™ M60 motor settings auto-configurator

- Three independent fiber or copper Ethernet ports for simultaneous/ dedicated network connections with 1 microsecond time synchronization via LAN with IEEE® 1588 support

- Reduced relay-to-relay wiring and associated installation costs through high-speed inter-relay communications

- Increase network availability by reducing failover time to zero through IEC® 62439-3 "PRP" support

- CyberSentry™ provides high-end cyber security aligned to industry standards and services (NERC® CIP, AAA, Radius, RBAC, Syslog)

- Robust network security enabling Critical Infrastructure Protection through user command logging, and dual permission access control

- High-end fault and disturbance recording

- Enhanced motor-learned data provides critical information for preventative maintenance

- Complete IEC 61850 Process Bus solution provides resource optimization and minimizes total P&C life cycle costs

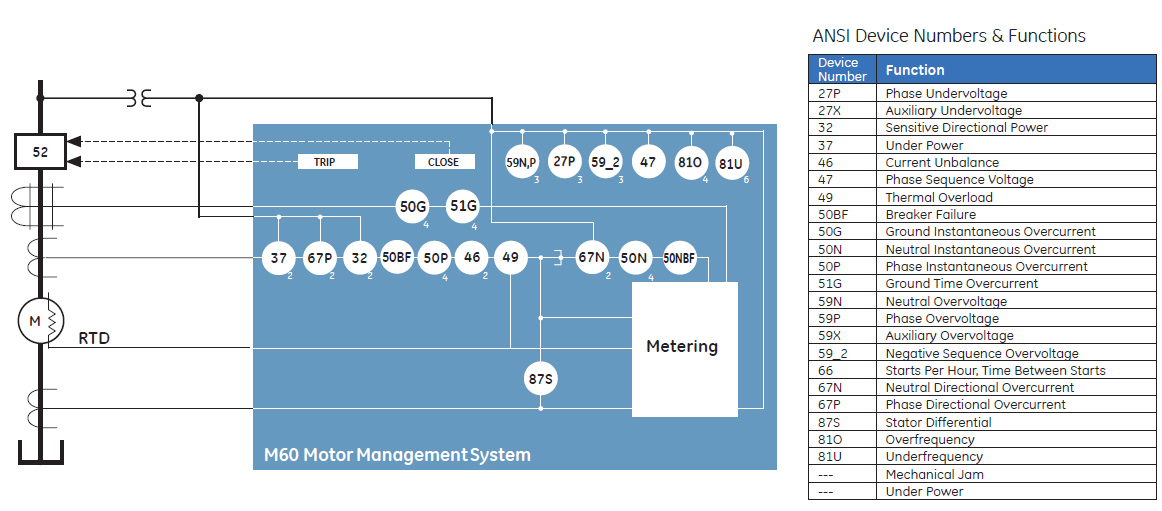

Functional Block Diagram